The Power

Amplifier

The design considerations

taken to arrive at the final design are detailed below .

Various options were considered

:-

A

pair of Single ended amplifiers with a splitter & combiner or "Push

pull " pair .

The next question of course is what type of

active device, Bipolar or FET

Given that a "Push pull

" style of amplifier should if the active devices have the same

electrical characterisics have a better performance , which means superior

suppression of "even " harmonics , this in turn means that filtering

requirements for remaining harmonics are also reduced .

The Amplifier circuit finally

chosen to give the required output power is a " Push - Pull " design

using a "Twin" package transistor ie one in which the two devices are

manufactured on the same die so that their characteristics are as near a match

as possible .

Then supply voltage for the

chosen device , obviously the higher the supply voltage ( within reason ) the

easier the matching of the device's impedance to the system impedance ( 50 Ohms

) so the choice between 12 V, 28 V & 50 V was settled in favour of the 50

volt devices , this does however reduce the choice of device available . There

were three types chosen MRF151G from Motorola ( On Semi ) BLF278 from Philips (

NXP ) and the D5028 from Semelab , in the end the D5028UK was chosen due mainly

to the lead time to obtain the device for another student's projects .

The amplifier was designed to

have a flat frequency response across the whole 2 meter amateur band by using

transmission lines for the matching networks rather than discrete components

this also has the advantage of increasing the reproducabilty of the design for

other constructors , the choice of PCB material dictates the size of the

completed amplifier as well as the size of the heatsink .

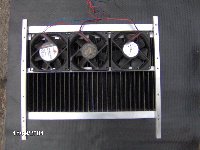

The heatsink size also

dictates the size of cabinet chosen for the completed design so that it could

be fitted in to the case , a small flow of air would be passed over the

heatsink using standard fans as used in computer power supplies, these can be

run at lower voltages to reduce the noise generated under normal operating

conditions if the heatsink temperature exceeds the required " Ambient

temperature " as used in the calculations then the air flow can be greatly

increased by using the fans at their rated supply .

The amplifier is biased into class AB as it is intended for

both SSB & FM modes of operation this means that it will be at best 50%

efficient so for 200 Watts output from the unit there will be at least 200

Watts of heat to be dissipated by the heatsink when in the input is an FM

signal, the mean value of an SSB signal being somewhat lower means that it will

run cooler . Due to the amplifier being intended to run at high power for

continuous operation the use of " FR4 " pcb material was eventually

discounted due to the transmission lines in the matching networks being too

thin to efficiently dissipate the heat due to the circulating currents , the

prototype amplifier used FR4 with " Smoky " results when the Drain

output matching network caught fire due to the inability to handle the

circulating currents ( It may also have been due to the use of a single

capacitor in this place ) so the final version of the amplifier used a "

Duroid " RT5870 - 060 - C1/C1 with 1oz copper " ( Although 2oz /

square inch would have been better ) , the area under the output transmission

lines being smeared with a thin film of heatsink paste to assist in the removal

of the heat . The construction of the

amplifier module case was from aluminium plate & bar stock from a local DIY

shop ,with only a small amount of machining done to attach the parts to the

heatsink the usual precautions are taken for any RF power module all

connections to it are either using coaxial connectors or feedthrough capacitors

preferably of the " Pi " type internal construction so that any RF

signals superimposed on supply or control / sensing wiring will be decoupled

from either direction all supplies & signal paths on the amplifier pcb are

also liberally filtered to minimise any stray resonances within the module's

case .The choice of capacitor for the RF matching circuits was down to either

the " ATC 100B " series of capacitor from " American Technical

Ceramics or the equivalent " CHB " series made by " TEMEX "

again due to the magnitudes of the currents involved " multiple parts were

used in parallel to ensure the reliability of the unit over time by minimising

the stresses induced in the devices , it's is possible to " Fuse "

the internal plates of the capacitor away from the end terminations due to

" I2R " losses within the device , the main tuning points for the

matching circuit had a small trimmer capacitor with PTFE dielectric to give

about 5% adjustment to optimise the match of both the input & output

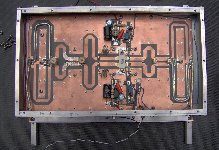

networks to system impedance ( 50R ).When first modelled it became obvious that

the transmission lines used in the matching circuits would be too long as

" Linear " circuits so the lines were redesigned into a series of

" Hairpin Loops " with short sections of transmission line parallel

to each other only where the chip capacitors needed to be ( see the layout /

circuit for more detail ) the width of the transmission line was chosen to be

near to system impedance for the mounting of the input & output "

Baluns " but was then remodelled using the width of the acitve device to

give a better heat dissipation / enable more capacitors in parallel to be used

this impedance was 43 R ( 6 mm wide track ).The amplifier's heatsink

temperature is measured using an LM35CZ temperature sensor in a small pocket

filled with a small amount of heatsink paste adjacent to the transistor this

produces a voltage output of 10mV / deg C for the control board .

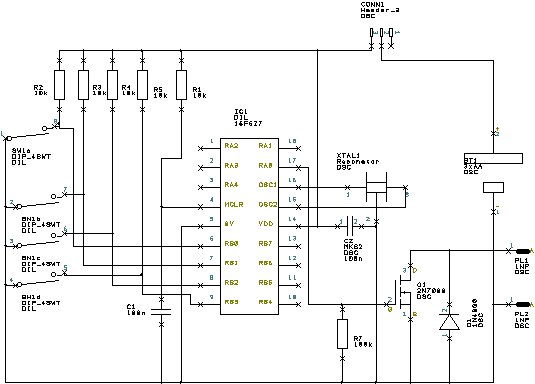

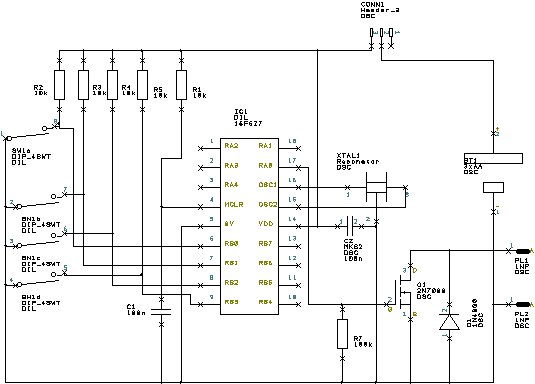

The amplifier as modelled

using " Microwave Office " below

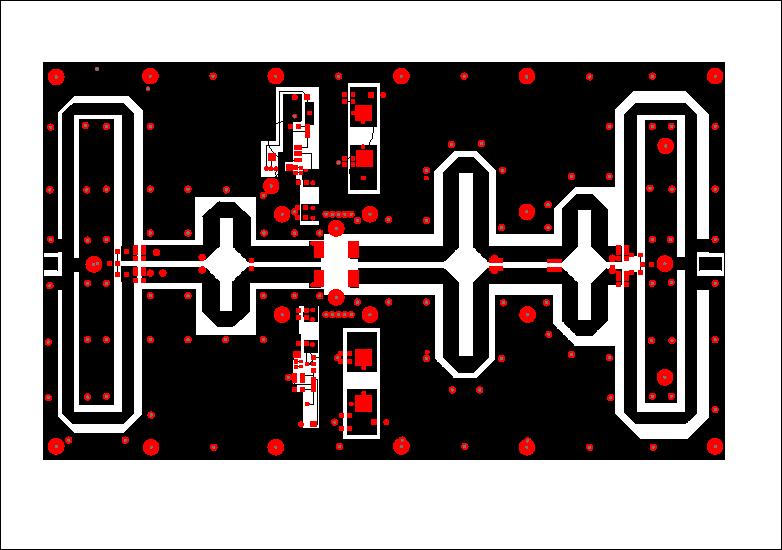

PCB Layout for the amplifier

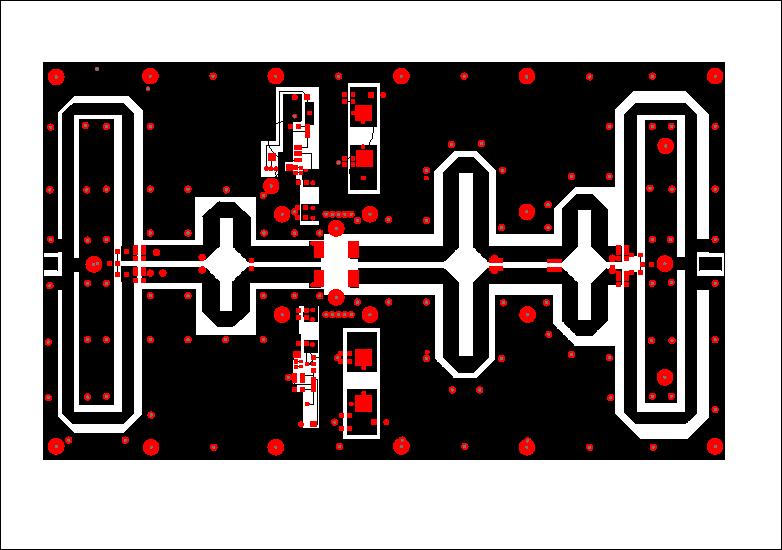

Mirrored Artwork for the amplifier

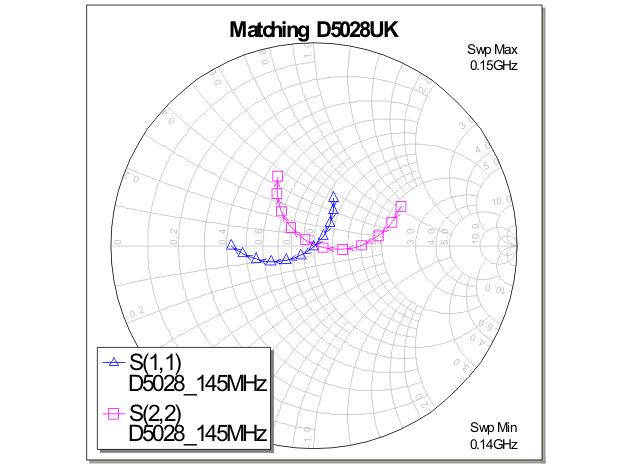

Screen shot of Input & Output Matching on

a Smith Chart as modelled using " Microwave Office " below

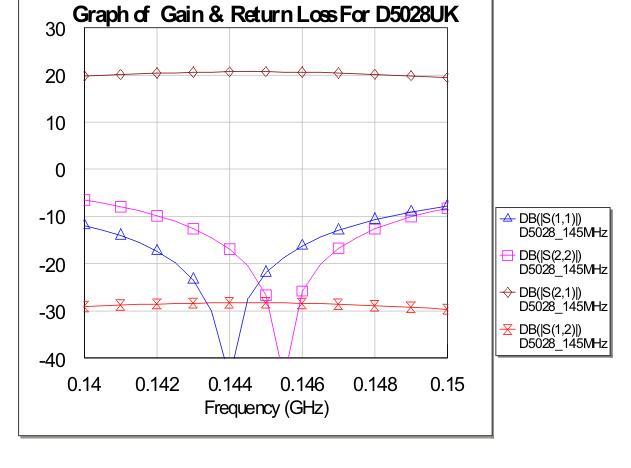

Screen shot of Amplifier Gain &

Return loss as modelled using " Microwave Office " below

The amplifier module during

testing as built below

Picture of completed amplifier

module with fans fitted during testing

The parts listing for the complete amplifier

module will appear shortly

Back To Table Top 200

Watt 145MHz Amplifier

This page last updated 10th Nov 2009